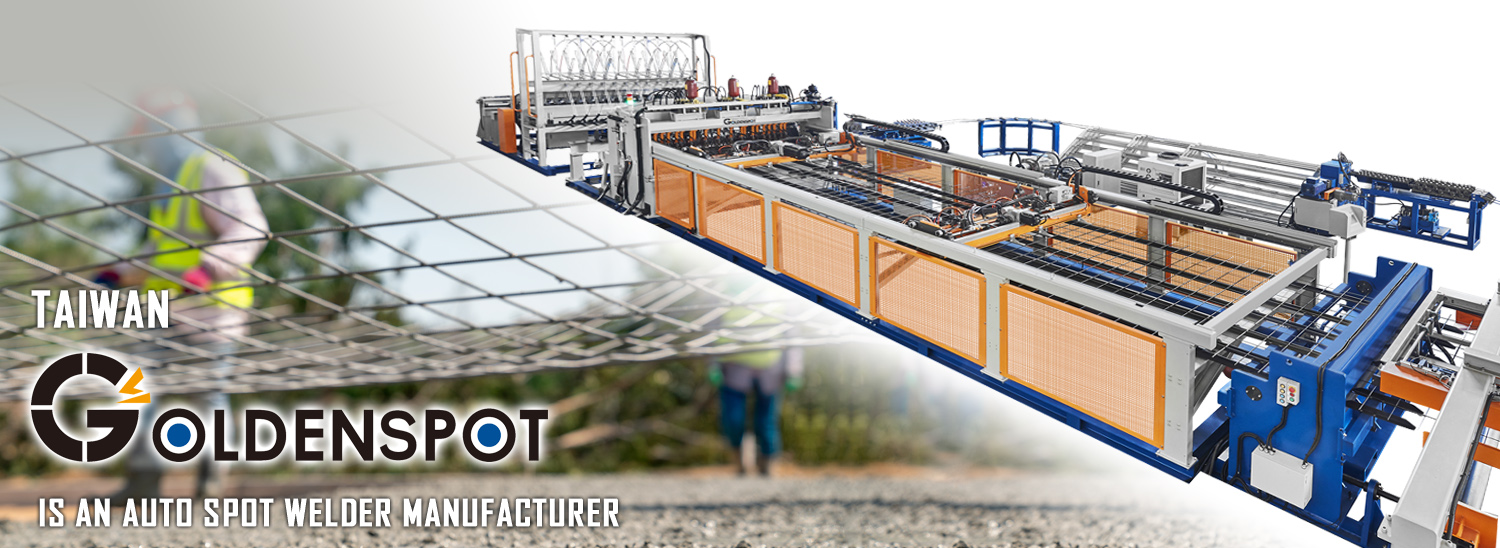

Golden Spot Industry Inc.

Since 1977, Golden Spot Industry is now a leading brand of spot welding machines in Asia Pacific. Through our strict quality control in each stage of the production process from design to finalize machine lines are accomplished under one roof. Our excellent R&D team with near 40 patents made our superior technology basis. With CE and ISO-9001 (R&D) certifications, we provide global standard professional services and machines.

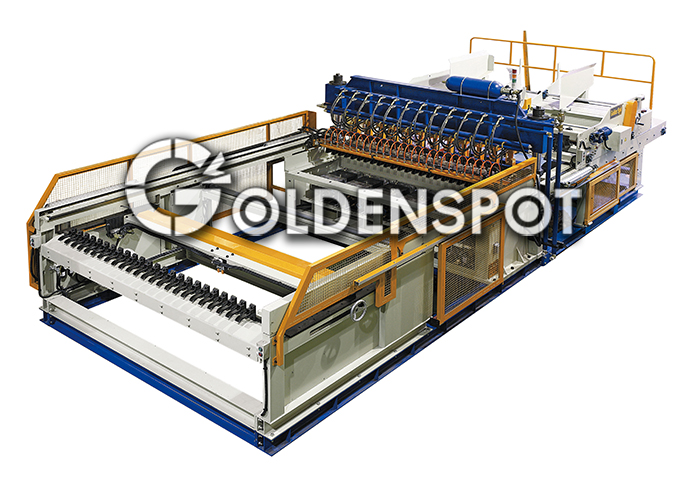

Hot Products

We are providing the best service quality

Quality

We have constructed a complete QC system, from incoming quality control, In-process Quality control to Final quality control.

R&D

ODM, according to customer needs, help customer to improve the production process.

Service

Immediate after-service, including maintenance, troubleshooting, and technical services.Golden Spot Industry Inc.

Copyright © 2022 Golden Spot Industry Inc.

All Rights Reserved.