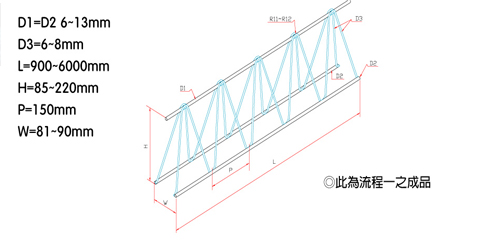

【Truss Construction / Lattice Girder】Whole plant Equipment

- ire feeder: 5 sets, width:2100m/m, the max load: 2 tons, adopting air-pressure brake.

- Straightening system: Composed of 5 sets straightening device, and applicable diameter is 6-20m/m.

- Storing system: storing the pre-straightened wire.

- Zigzag forming system: Adjusting the Zigzag height by motor which save laborers and easy adjusting.

- Welding System: Equipped with 2 sets of 200KVA transformers and our own developed controller to be in the process of welding.

- Pushing and cutting system: Operated by Oil-pressure system, 30nt/in max output, steady and quick.

- The above is process 1 which suits for railroad tie, rigid frame of plant roof, floor, and so on.

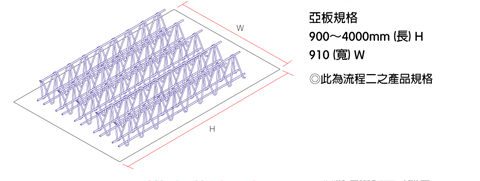

- Holding System: Holding the finished workpiece to the terminal. It can be easily to be integrated with other working process.

- Bottom Plate System: leveling the bundle of bottom plate, and cutting to the set length.

- Multi-point Spot Welding: Weld 5 sets of zigzag truss with bottom plate.

ures

The bottom plate structure, applying to shell structure, floor, successive wall, replaces the traditional type and shortens work time.