What is MFDC welding machine?

MFDC stands for Mid Frequency Direct Current, and MFDC welding refers to a type of resistance welding that utilizes a mid-frequency direct current power source. This welding process is also known as Medium Frequency Direct Current (MFDC) resistance welding or simply mid-frequency welding.

Here are the key features and aspects of MFDC welding:

-

Power Source:

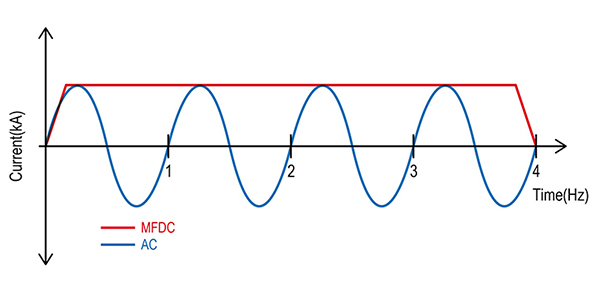

- Unlike traditional resistance welding processes that use Alternating Current (AC), MFDC welding employs a direct current (DC) power source.

- The frequency of the current is in the mid-frequency range, typically between 400 and 4000 Hertz.

-

Transformation Process:

- The three-phase AC input is converted to a mid-frequency output through an inverter.

- The resulting high-frequency current is then transformed to produce a continuous DC output.

-

Continuous Heating:

- MFDC welding provides a continuous and controlled flow of direct current to the welding operation.

- Unlike AC welding, there are no zero crossings in the waveform, leading to uninterrupted and rapid heating.

-

Fine Control and Timing:

- The timing in MFDC welding is measured in milliseconds (ms).

- This precise timing allows for fine control over the welding process, contributing to better control of heat input and improved welding results.

-

Reduced Inductive Losses:

- MFDC welding systems typically experience reduced inductive losses compared to traditional AC welding.

- This efficiency can lead to lower power requirements and improved energy utilization.

-

Smaller Transformers:

- MFDC transformers can be made smaller than their AC counterparts due to the higher operating frequencies.

- The reduced size contributes to lower weight, making MFDC welding systems more suitable for automation applications.

-

Versatility:

- MFDC welding is known for its versatility and adaptability to different materials and thicknesses.

- The process is suitable for a wide range of applications, including spot welding, seam welding, and projection welding.

-

Automation and Robotics:

- The precise control and efficiency of MFDC welding make it well-suited for automation and robotic welding applications.

- The reduced weight and size of the equipment enhance its compatibility with robotic systems.

In summary, MFDC welding represents an advancement in resistance welding technology, offering improved control, efficiency, and adaptability. Its continuous DC output, precise timing, and reduced inductive losses make it a preferred choice in various industries, especially in automated manufacturing processes.